CSD in Action: Understanding Important Particle Properties and Their Effects on Pharmaceutical Formulation and Manufacturing

In the latest in our 'Tools in Action' series — highlighting research that draws on the wealth of knowledge in the Cambridge Structural Database (CSD) and CCDC software to enhance and mine the data from the 1.1M+ crystal structures — a collaboration between five organisations used software now available in the CSD Particle suite to assess and predict particle properties that influence pharmaceutical formulation and manufacture.

Reporting in Crystal Growth & Design (2019, 19, 9, 5258–5266; doi.org/10.1021/acs.cgd.9b00654),1 the team from Pfizer, GlaxoSmithKline, the University of Leeds, Britest and the CCDC, used a combination of established solid form informatics and new predictive digital design tools to propose a new knowledge-based workflow. This will help formulation chemists to make decisions at key stages of pharmaceutical manufacturing based on knowledge of particle properties. The software used has subsequently been been enhanced and released in the new CSD Particle suite.

The research was carried out as part of the ADDoPT (Advanced Digital Design of Pharmaceutical Therapeutics) project, a four-year collaboration between pharmaceutical companies, solution providers and academia to develop and implement advanced digital design techniques that eliminate non-viable drug candidate formulations as early as possible, streamlining design, development and manufacturing processes.

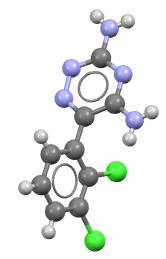

As a drug of study, the researchers used the antiepileptic lamotrigine (CSD Refcode: EFEMUX01), a much studied ‘model’ drug (and also the 500,000th structure in the CSD).2 Solid form informatics calculations using data from the 1.1M+ structures in the CSD showed that the known anhydrous form of lamotrigine was the most stable with crystal packing arrangements as expected.

The anhydrous form of the antiepileptic drug lamotrigine (CSD Refcode: EFEMUX01).

The anhydrous form of the antiepileptic drug lamotrigine (CSD Refcode: EFEMUX01).

However, the behaviour of lamotrigine during formulation and manufacturing presents many issues, including poor powder flow properties and poor compressibility – the latter leading to ‘capping’ upon tableting.

Predicting and avoiding these issues in advance of manufacture will save pharmaceutical companies time and resources by reducing the amount of experimental research needed to try and identify these potential bottlenecks.

Particle Informatics Workflow

The team used a combination of predictive digital tools now included in CSD Particle and methods that focus on intermolecular interaction energies, to propose a workflow that builds on the knowledge from each step to avoid these and other formulation issues in small molecule pharmaceutical manufacturing.

Using lamotrigine as an example, each step of the particle informatics workflow is explained, providing insights into solid particle behaviour along the manufacturing journey. A thorough analysis of particle behaviour at each stage is presented, including:

- Intermolecular interactions and energetic analysis

- Mechanical property prediction and analysis

- Particle morphology calculation and analysis

- Surface energy and topology analysis

- Analysis of surface interactions.

The New CSD Particle Suite – Transform Pharmaceutical and Fine Chemical Manufacturing by Anticipating and Eliminating Potential Bottlenecks

Recently added to the CCDC software portfolio, the CSD Particle suite of informatics tools draws on the data from 1.1M+ validated crystal structures in the CSD to anticipate manufacturing bottlenecks and guide formulation decisions with a deep understanding of particle behaviour. Manufacturing bottlenecks anticipated include flow, wettability, tabletability and sticking.

On-Demand Learning – Surface Analysis with CSD-Particle

This free training module explores tools for particle analysis, in particular from the CSD-Particle suite. You will see in detail how to analyse small molecules particle surfaces using the Surface Analysis functionality, which enables you to assess the topology and the chemistry of the surface as well as estimate likely interactions.

References

- Mathew J. Bryant, Ian Rosbottom, Ian J. Bruno, Robert Docherty, Colin M. Edge, Robert B. Hammond, Robert Peeling, Jonathan Pickering, Kevin J. Roberts, and Andrew G. P. Maloney, “Particle Informatics”: Advancing Our Understanding of Particle Properties through Digital Design, Crystal Growth & Design, 2019 19 (9), 5258-5266, DOI: 10.1021/acs.cgd.9b00654.

- Galek, P. T. A.; Pidcock, E.; Wood, P. A.; Bruno, I. J.; Groom, C. R., One in Half a Million: A Solid Form Informatics Study of a Pharmaceutical Crystal Structure, CrystEngComm 2012, 14 (7), 2391– 2403, DOI: 10.1039/C2CE06362J.

Next Steps

See how CCDC software, including CSD-Particle, can help your pharmaceutical research.

Read more case studies about CCDC data and software being used in industry and academia.

Learn more about the Cambridge Structural Database (CSD) and how the validated, curated data of 1.1M+ crystal structures can aid your research.