Rapidly Identify Solid Forms

Easily Match Your Experimental PXRD with a Crystal Structure

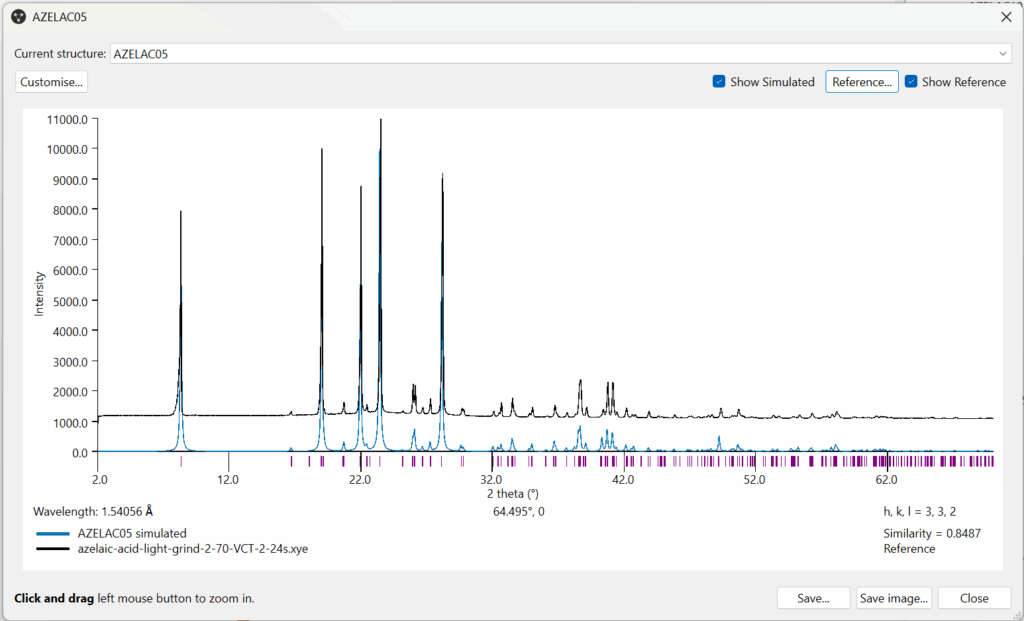

One of the most popular features in Mercury is the ability to simulate a powder pattern from a crystal structure, to compare it to experimental powder patterns.

You can now import experimental PXRD patterns to Mercury, enabling rapid comparison and matching within an easy-to-use interface. This will accelerate the workflow for powder pattern comparison for CSD-Materials license holders (including paid academic licences).

How to Use the New Functionality

The powder pattern dialog can be opened in Mercury either via the PXRD button on the Display Options toolbar or through the Calculate → Powder Pattern… menu item. A new ‘Reference’ button on the top right allows you to load in a reference PXRD file in .xy, .xye or .xrdml formats for straightforward comparison with simulated patterns. The simulated and reference powder patterns will be normalised to enable clear visualization. A legend allows easy identification of the patterns being compared.

A new Similarity score is also provided at the bottom right of the dialog, calculated using similarity measures by de Gelder et al., also used in AutoFIDEL. This enables rapid identification of closely matching patterns. For example, if you know there are several polymorphs to compare in a refcode family or in-house database, you can rapidly flick through these in structure navigator, and the simulated pattern for each will be displayed against the experimental reference with a calculated Similarity score. This allows you to quickly identify the closest matches for closer inspection.

New Visualization Options

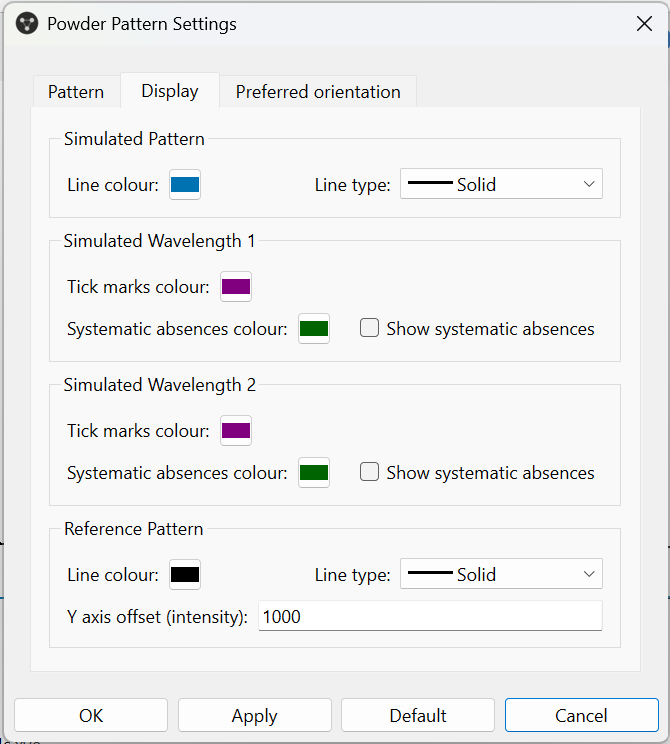

The Customize… button has some additional features — the display tab now allows you to choose the colours for use in displaying both the simulated and the reference patterns, as well as choosing different line types for clearer differentiation and improved accessibility. There is also a Y axis offset figure, which allows you to separate or overlay the patterns as they compare them.

What’s Next?

We will soon bring full crystal structure optimization using AutoFIDEL into the powder pattern dialog for our CSD-Materials customers. This functionality enables high-quality matching and optimization of structures with reference powder patterns. AutoFIDEL is particularly useful for both predicted crystal structures and low-temperature experimental crystal structures, where the powder pattern is measured under significantly different conditions, which can result in differences in lattice parameters and powder patterns.

To discuss further and/or request a demo with one of our scientists, please contact us via this form or email us here.