What Is Stopping MOFs Being More Widely Used?

In this blog we look at the current status of metal-organic frameworks (MOFs) in the global market, investigate some challenges that are still impacting their growth, and explore opportunities for future developments in the functional materials field.

What Are MOFs and Why Are They Important?

The term ‘metal-organic framework’ was coined back in the 1990s by Professor Omar Yaghi, called “The man of MOFs and more” in this recent interview published in Nature Reviews Chemistry [1].

Metal-organic frameworks, or MOFs in short, are porous functional materials constructed with metal centres (or metal clusters) and multidentate organic ligands.

The structure of MOFs, and hence their pore sizes and features, are highly tuneable, making these materials excellent for applications in gas adsorption and separation, energy storage and conversion, catalysis, sensing, and more.

A Look at the Global Market of MOFs

Since their discovery, the number of MOFs has grown exponentially, and so have their uses in a variety of research fields and industries.

Recent research shows that the global MOF market size is forecasted to increase from USD 751.65 million in 2024 to approximately USD 2,258.26 million by 2034 [2].

This remarkable increase is expected to be driven by some key factors that include the rising demand for efficient carbon capture and water harvesting materials, and the growing use of MOFs for catalytic, electronic, and pharmaceutical applications [2].

However, despite the significant advancements seen in the past decades in controlling with increasing precision the design and synthesis of new MOFs, there are still factors that slow down their development both on a small scale and on industrial level.

Will research ever be able to overcome these factors? Will more work in engineering these materials make them reach their full potential? And how can this be done?

Challenges in Designing MOFs

Designing MOFs with specific properties is challenging on multiple levels.

The choice of the ligands, metal centres, solvents, reaction conditions, and synthetic methods highly influence the morphology of the final MOF, which in turn affects its properties. Understanding the structure–property relationships is hence critical for the rational design of new MOFs with desired functional applications [3].

Structure–Property Relationships in MOFs

Recent research on a series of pyrene-based MOFs for carbon capture investigated the role of structural variations on the CO2 uptakes and adsorption properties of the materials [4], [5].

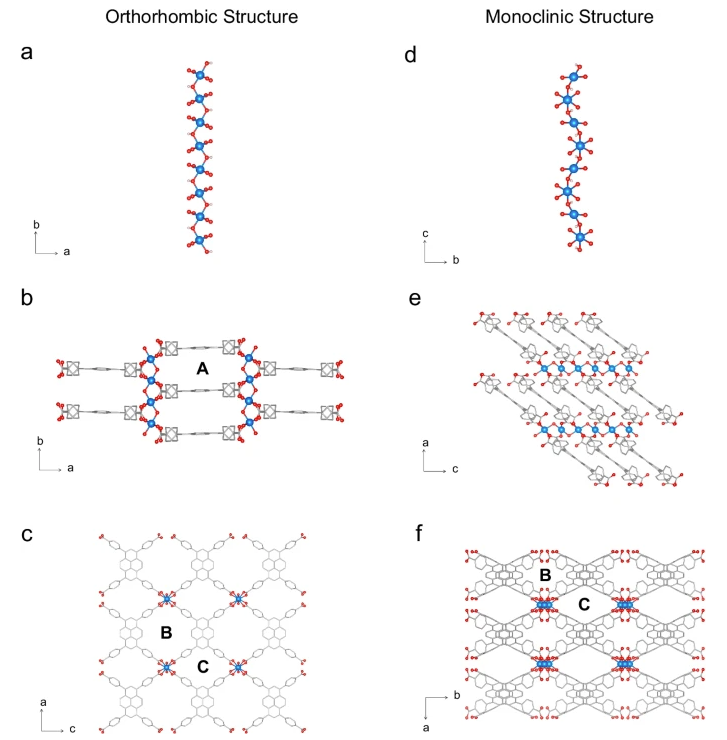

The team studied a family of MOFs constructed using the same pyrene-based organic ligand, whose parallel aromatic rings are promising for CO2 capture, and different metal centres. Structural analysis revealed that an orthorhombic structure (Figure 1a, b, c) is obtained for the pyrene-based MOFs constructed with Al(III) and Sc(III), and maintained after activation with CO2, H2, and H2O. A monoclinic structure (Figure 1d, e, f) is instead obtained for the Ga-based MOF, where a rotation of the benzoate groups of the ligand breaks the linear arrangement of the metal ions, leading to a shift of the ligands in the structure.

From Figure 1 it is clear how these structural changes affect the CO2 uptake in these MOFs: while the orthorhombic structure features perfectly stacked pyrene ligands, the latter are no longer parallel and at a much shorter distance in the monoclinic structure, making it hard for CO2 to be adsorbed.

But this isn’t all. Further analysis also showed that a structural rearrangement might be occurring upon CO2 loading at high pressure for the monoclinic In- and Ga-based MOFs. In fact, these MOFs exhibited adsorption isotherms similar to those calculated for the orthorhombic structures, suggesting that a phase transition from the monoclinic structures could occur upon CO2 insertion.

This is just one of many existing examples of research on structure–property relationships in MOFs. The work demonstrates:

- Key challenges with structural control and properties tuning that the researchers working with MOFs face on a daily basis

- The structural studies which must still be performed to rationalize pores properties

- How the guest molecules themselves can have an impact on the structures of porous materials and on their performance

Challenges in Bringing MOFs to Industry

On an industry level, the production of MOFs is further complicated by the high costs of manufacturing these materials, and the lack of manufacturing methods that are scalable and environmentally sustainable [2].

Interestingly, there are only a handful of commercial MOF products compared with the over 100,000 known structures [6], indicating how challenging it still is to commercialize MOFs.

BASF is at the forefront of MOFs production on a commercial scale, being the first company that in 2023 successfully scaled up the production of MOFs for carbon capture to several hundred tons per year [7].

Find more information on how to tackle challenges when transitioning from the research laboratory to commercial use when working with MOFs in this perspective published in Nature Materials [8].

AI and ML: An Opportunity to Advance MOFs Research

According to the global market analysis mentioned above [2], the integration of AI and ML technologies in MOFs research represents a great opportunity for advancing discoveries in industry in this field. In particular, this approach supports manufacturers with optimizing and predicting the properties of a variety of MOFs.

Professor Omar Yaghi [1] as well believes that the integration of AI will become the driving force to accelerating materials discoveries and will revolutionize the way we design and deploy them.

How Does AI and ML Help in MOFs Research?

The use of computational science in MOFs research, in particular through AI predictions, enables a more precise and efficient design of new MOFs and synthetic procedures.

In this review [9], researchers investigated recent progress in the field, showing how research has focused primarily on developing models that can:

- Rapidly screen the extended chemical spaces and analyse large amount of experimental data

- Predict MOFs stability and performance

- Suggest novel MOFs with desired features

Essential for building and training models is to start from a database. This data feeds the model, allows it to find patterns and correlations that might not be easily identified by humans, and ultimately enables it to perform better predictions [9].

Next Steps

- Read our white paper Accelerating Porous Materials Design and Development—A Data-Driven Approach on data, software, and a comprehensive workflow for advanced porous materials research.

- To explore more how to visualize and analyse MOFs, see our blog How to Search, Visualize, and Analyse MOF Structures.

- To discuss further and/or request a demo with one of our scientists, please contact us via this form or .

References

[1] Nat Rev Chem 9, 135–137 (2025).

[2] Metal Organic Framework Market Size to Hit USD 2,258.26 Million by 2034.

[3] Materials Today, 27, 43–68 (2019).

[4] MOFs & Structures: How does Changing the Metal Affect CO2 Uptakes.

[5] Nat Commun 16, 1516 (2025).

[6] Nat. Mater. 24, 157 (2025).