Particle Analysis Improves Outcomes in Pharmaceutical and Crystalline Materials Design

We are excited to highlight that the CSD-Particle suite of advanced informatics tools is now being actively used to revolutionize the understanding of particle behaviour and surface properties in pharmaceutical and fine chemical manufacturing. The suite provides easy to use digital methods to enhance the efficiency of product formulation and reduce manufacturing costs.

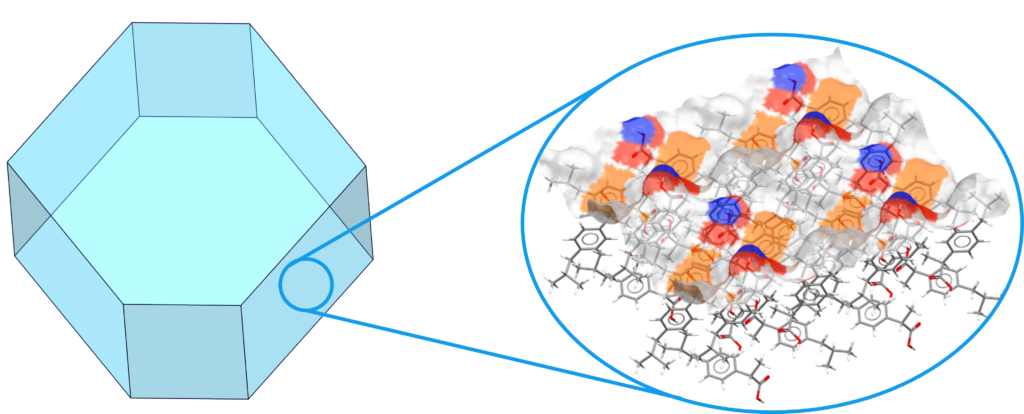

A study published in Crystal Growth & Design, Surface Analysis – From Crystal Structures to Particle Properties, highlights the suite’s ability to visualize and quantify chemical and topological information from crystallographic data. Applied to the case study of punch sticking for ibuprofen particles, this approach can reduce the need for expensive trial-and-error methods by providing data-driven guidance for formulators and particle engineers.

Another study in Crystal Growth & Design, Identifying Possible Slip Systems of Molecular Crystals via a Geometry-Based Procedure, builds on a previously published method (Predicting mechanical properties of crystalline materials through topological analysis) to identify slip systems in molecular crystals developed by CCDC scientists by using a steric hindrance parameter to quantify molecular overlap as an impediment to slip. This efficient procedure helped to predict the plasticity of energetic materials, supporting better design for these complex products.

A third study in Powder Diffraction, Predicting Particle Quality Attributes of Organic Crystalline Materials using Particle Informatics, explored the surface properties of crystals of a novel quercetin solvate of dimethylformamide (QDMF). Using CSD-Particle, researchers explored key features of the QDMF particles and validated their findings with experimental methods such as Atomic Force Microscopy (AFM), demonstrating the suite’s accuracy and utility.

CSD-Particle is part of our commitment to enhancing the efficiency and effectiveness of pharmaceutical and fine chemical manufacturing. Designed in collaboration with leading academic and industrial partners, including AstraZeneca, Bristol-Myers Squibb, GlaxoSmithKline, and Pfizer, CSD-Particle tools were developed through collaborative projects such as the Advanced Digital Design of Pharmaceutical Therapeutics (ADDoPT) and the Digital Design Accelerator Platform (D-DAP). Both initiatives aim to shift pharmaceutical development to a ‘digital first’ approach, minimizing non-viable drug candidate formulations and anticipating manufacturing bottlenecks early in the process.

“Science is evolving, and so is the CCDC. Our CSD-Particle suite, released in 2022, for the study of the surface properties and the mechanical properties of crystalline materials, is becoming increasingly essential to save valuable time, costs, and resources. Used primarily, but by no means limited to, drug discovery and delivery, I’m delighted to see CSD-Particle-based research now being published in the scientific literature,” said Dr Jürgen Harter, CCDC CEO.

CSD-Particle can provide insight into surface chemistry and topology. Here, hydrogen bond donors, hydrogen bond acceptors, and aromatic groups on the surface are highlighted in blue, red, and orange respectively.

While the primary application of these tools will be in drug development, their utility extends to the development of agrochemicals, such as pesticides, and other advanced materials and formulated products, where early knowledge of surface properties is advantageous.

These innovations mark a significant advancement in the comprehensive understanding of particle surfaces and their impact on product performance, supporting formulators and particle engineers in making informed, data-driven decisions.

Next Steps

To discuss further and/or request a demo with one of our scientists, please contact us via this form or email us here.