Exploring Pharmaceutical Chemical and Mechanical Properties with CSD-Particle – Your Questions Answered

Eliminating potential manufacturing bottlenecks before they occur is highly advantageous in all industries.

In the pharmaceutical, fine chemical and agrochemicals industries, understanding particles' chemical and mechanical properties is key. By performing particle shape and surface analyses, crystallisation scientists, formulators, computational materials scientists and particle scientists can anticipate manufacturing issues such as sticking, wettability, and tabletability. The potential savings associated with avoiding these manufacturing issues run into the £millions.

This is where CSD-Particle comes in – our new suite of software, drawing on the data from 1.2M crystal structures held in the Cambridge Structural Database (CSD) – that provides researchers with visual displays of surface chemistry, charge and topology that can then be used to guide manufacturing decisions, eliminating potential bottlenecks before they occur.

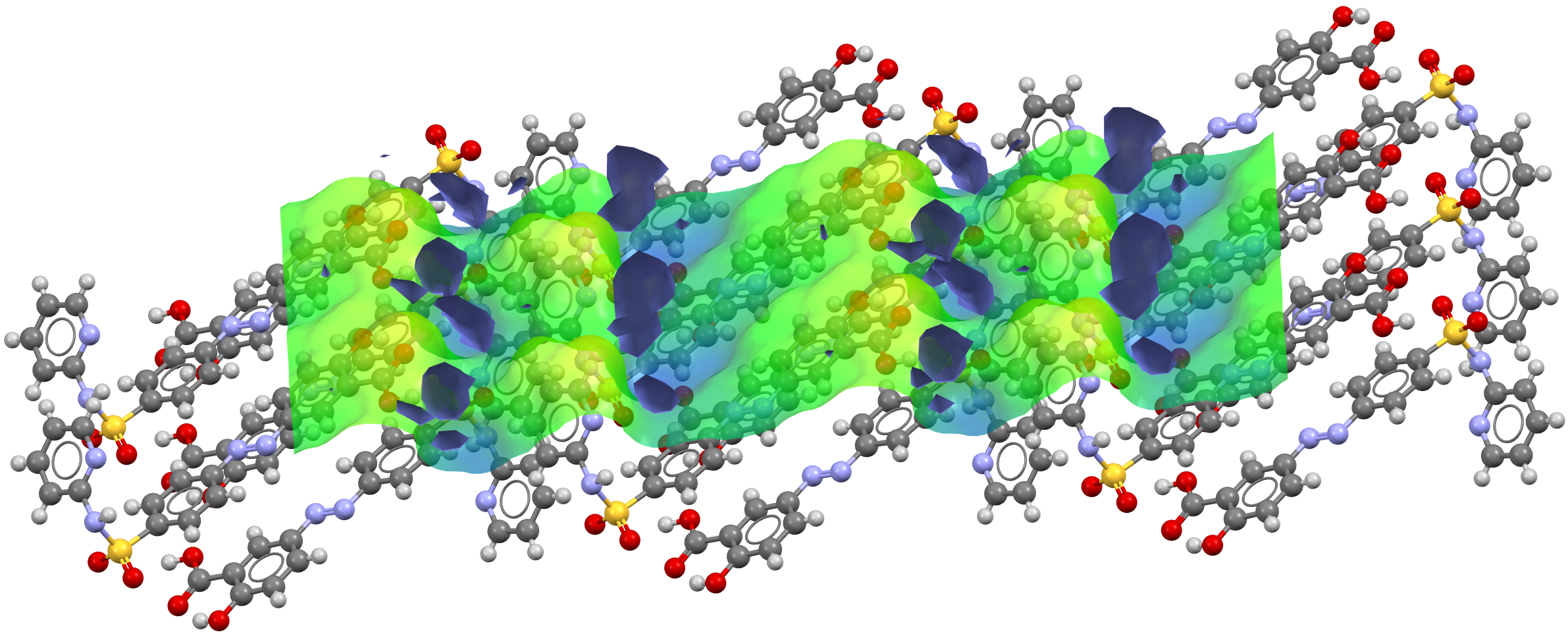

Topological view of the [010] surface of Sulfasalazine showing regions of probable intermolecular interactions with water molecules.

Topological view of the [010] surface of Sulfasalazine showing regions of probable intermolecular interactions with water molecules.

We recently ran a global workshop with attendees from 36 countries on how to visualize and analyse surfaces using CSD-Particle in Mercury. The workshop covered the link between crystal structures and particles, and how to understand the mechanical and chemical properties of those particles, by identifying and analysing potential slip planes, conducting surface analysis, and calculating Full Interaction Maps (FIMs) on surfaces.

Here are some of the questions that came up during that workshop:

Q. Can CSD-Particle predict manufacturing bottlenecks?

A. Yes! In pharmaceutical, agrochemical and fine chemical manufacturing, potential issues in wettability, flow or sticking, tabletability, and electrostatic interactions can be identified at an early stage, reducing costs and time.

Q. What form are CSD-Particle results given in?

A. Results can be either visual or numerical. Interactive 3D visualizations will allow you to quickly compare facets, particles, or structures by quantifying the density of H-bond donors, acceptors, aromatic bonds, unsatisfied H-bond donors, RMSD, surface area, rugosity, kurtosis, and skewness.

Q. Is it possible to correlate the surface properties with the surface energies of a material? If it is possible, can you elaborate how to do that?

A. In terms of the surface chemistry and charge, where highly charged surfaces, or surfaces with a lot of hydrogen bond donors/acceptors, are likely to be more energetic. We’re also working on methods to make it possible to use an understanding of intermolecular energies to calculate growth directions etc. (and so to predict morphologies, for instance). These energies can feed into other workflows to think about how particles stick together, or to think about breakage/dislocation and mechanical properties.

Q. Could I extrapolate results from CSD-Particle to coordination complexes, polymers or to porous surface analysis?

A. The methods can work for these structures, but they have not been optimised for it – they are currently focused for small organic molecules. A number of the components, including FIMs, will not work on transition metals, and so might not be appropriate for some systems that you are interested in.

Q. Can slip planes also predict the propensity of cracking of a crystal? Could you combine this with a BFDH morphology prediction to predict the morphologies of milled crystals?

A. We have previously used slip planes to understand tabletability and the link between crystal structure and mechanical properties – please see Predicting mechanical properties of crystalline materials through topological analysis for more details of that and the validation. The link between breaking/cracking of a crystal and the corresponding morphology is very interesting and something we’re keen to explore in more detail.

Q. How is CSD-Particle accessed?

A. The analytical tools in CSD-Particle can be accessed through our desktop program Mercury, or via the CSD Python API. The functions are available to all academic researchers, non-academic users require a CSD-Particle licence—contact us here to request a quote, demo, or trial.

Next Steps

Request the workshop recording, handouts and slides and then work through the examples.

More information on the CSD-Particle suite.

Register for an upcoming workshop.

Read the CSD-Particle launch release.

Check out the CSD-Particle case study – Understanding Important Particle Properties and Their Effects on Pharmaceutical Formulation and Manufacturing.