CSD in Action: Optimizing Metal-Organic Frameworks for the Recovery of Volatile Organic Compound Emissions

Here we highlight a paper by authors at Tianjin University who used the CSD MOF Subset to optimize materials for the recovery of volatile organic compound (VOC) emissions. This is part of our series highlighting examples of the Cambridge Crystallographic Data Centre (CCDC) tools in action by scientists around the world.

Summary

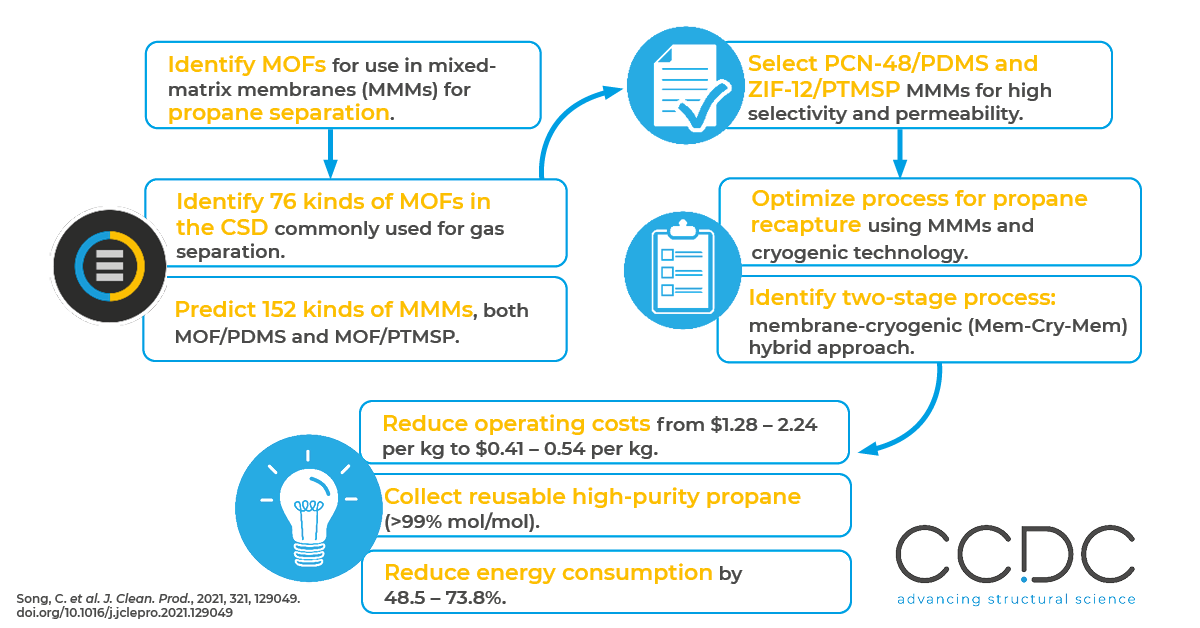

VOC emissions from chemical production and petroleum refining waste resources and cause environmental pollution. Recapturing such VOCs, like propane, has both environmental and economic value. Here, the authors computationally screened and then selected metal-organic frameworks (MOFs) for membrane-based separation, and then optimized the process for utilizing those materials for propane recapture. They relied on computational techniques to optimize the MOFs, leveraging the experimentally derived structures from the Cambridge Structural Database (CSD), via the CSD MOF Subset. Specifically, the authors optimized mixed-matrix membrane (MMM) materials using 76 kinds of MOFs commonly used for gas separation, including zeolitic imidazolate frameworks (ZIFs), isoreticular metal-organic frameworks (IRMOFs), Materiau de l’Institut Lavoisier (MIL), and porous coordination networks (PCNs).

Results

Using the structures from the CSD, the authors virtually screened 152 kinds of MMMs, some using MOFs and polydimethylsiloxane (PDMS) and some using MOFs and hydrophobic polymers showing solubility (PTMSPs). The authors found that applying these MMM to an overall optimized two-stage membrane-cryogenic (Mem-Cry-Mem) hybrid process presents significant technological and economic potential in the field of VOCs recovery at high and low concentrations, including:

- A reduction in common related operating expenses from a range of $1.28–2.24 per kilogram (kg) to a range of $0.41–0.54 per kg.

- An increase in the condensation temperature from a range of -131 to -110 Celsius (C) to a range of -105 to 72 C.

- The collection of reusable high-purity propane (>99% mol/mol), with energy consumption reduced by 48.5 to 73.8%.

- Compared to the pure PDMS polymer membrane, the selectivity and permeability of PCN-48/PDMS increased by 172% and 70.4%, respectively. The selectivity and permeability of ZIF-12/PTMSP increased by 230% and 108%, respectively.

How

The researchers took a two-pronged approach. First, they completed molecular optimizations for the materials in the MMMs. They ran the Monte Carlo (GCMC) simulation method with a software package called RASPA and used MOF structures from the CSD. They then optimized the two-step membrane-cryogenic (Mem-Cry-Mem) hybrid process for directing the exhaust through those membranes with PROII 10.0 software.

Why

There are several technologies for propane recapture; however, on their own, such technologies often have low recovery rates and relatively high cost and energy requirements. Here, the researchers combined two known technologies used in propane recapture: membrane materials and cryogenic condensation. Cryogenic technology can effectively recover propane from the exhaust and obtain a high-purity liquid propane product, but it usually demands a lot of energy for cooling due to the required low-temperature conditions. According to the authors, membrane separation technology is considered a fairly efficient purification approach, and benefits from low energy requirements, high recovery rates, and flexible design. It’s also easy to couple with other technologies during overall process design. However, correctly identifying materials for the membranes requires a lot of high-quality, relevant data, which they obtained from the CSD.

Read more

Read the paper: “Optimization of membrane-cryogenic hybrid propane recovery process: From molecular to process simulation.” J. Clean. Prod, 2021, 321.

Learn about the CSD MOF collection, which contains over 10,000 MOF crystal structures free for use in academic research. (This is a subset of the over 100,000 MOF-like frameworks in the CSD.)

Learn more about applications of MOFs, CCDC’s on-demand webinars about MOFs, available tools for MOFs analysis, and more!

Read additional case studies in our “Tools in Action” series.