Matwalls: Thinking about risks in the development of new materials

When we think about risks, lots of different things can come to mind but underpinning them all is the chance that something undesired may happen. If we didn’t take risks then few worthwhile accomplishments would ever be made. It’s through understanding these risks, assessing the risk / benefit profile and things we can do to improve that profile that we are able to manage risk and move forward.

Over the last few months I’ve had the great pleasure of spending some time with Simon Black and working with him to write a white paper on “Matwalls”. Simon and I come from similar backgrounds within the pharmaceutical industry but from different organisations so initially I had no idea what he meant by a Matwall! But within a couple of minutes of discussion it was clear to me what the concept was and how it fitted within very familiar workflows.

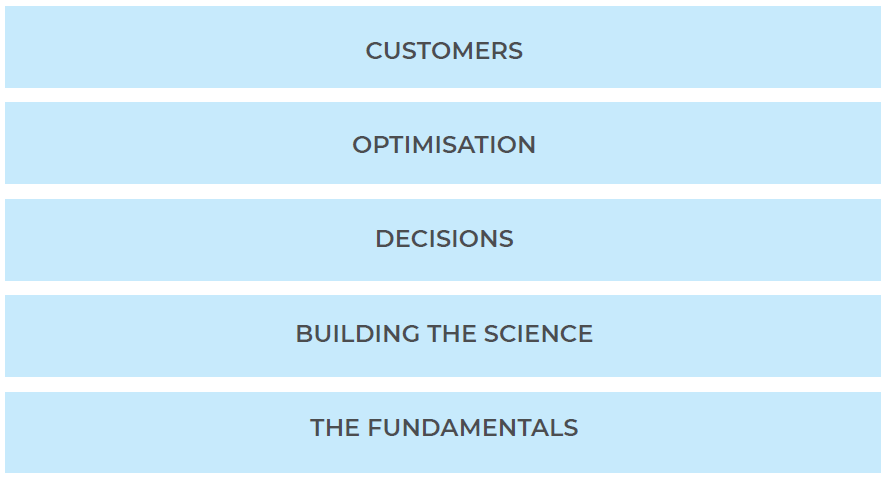

In essence, a Matwall is a tool to facilitate a materials-based risk assessment of an active pharmaceutical ingredient through its commercial process development. Like a wall, it is built from the bottom up but knowing the makeup of the layers to come provides focus on the end goal, successful treatment of a patient. This kind of framework helps to ensure the right work is done, with the right focus, at approximately the right time in the development cycle for a new material.

Figure 1: The 5 layers of a Matwall. Additional ‘bricks’ make up each layer.

Within the Matwall framework the use of structural chemistry in the foundational layers is key. The crystal structure of the desired material is the building block for all other properties and behaviours the material is likely to show through processing and can highlight some of those risks early on in development. Having this knowledge at the right time can guide experimental efforts in the right way to minimise wasted resources and maximise the chances of success. Tools that have been developed based on the CSD can be used to help with the predictive understanding of these risks (https://info.ccdc.cam.ac.uk/solid-form-informatics-for-pharmaceuticals-and-fine-chemicals and Bryant, M.J. et al. Cryst. Growth Des. 2019, 19, 9, 5258-5266).

The upper layers focus on process definition and optimisation, technical transfer, material attributes which could change on processing or storage and regulatory requirements. A good understanding of the crystal structure and the properties it sets helps to understand, and in some cases predict, challenges in late stage process development.

I believe that frameworks like this one are a really useful tool in helping to show where there are challenges within a process and where to put additional efforts to robustly get a drug to patients. They can also act as knowledge management tools through a product lifecycle and the act of completing a framework like this can share that knowledge across development and manufacturing teams increasing its awareness and use. Hopefully reading through the white paper will stimulate new ideas for how we can use structural chemistry data even more effectively, both within and even perhaps outside of pharmaceutical development workflows.

If you are a process engineer, crystallisation expert, materials scientist or if you are accountable for CMC elements of technical transfer and regulatory submission then the Matwall approach could be really powerful for you and your organisation in understanding materials-based risks. I’d love to hear your thoughts once you’ve read the white paper, you can contact us at .

Download the Matwall white paper here.